- Home

- |

- Products

- |

- PuraBead® Resins

- |

- Affinity

- |

- EtoxiClear®

EtoxiClear®

Product Overview

Product Overview

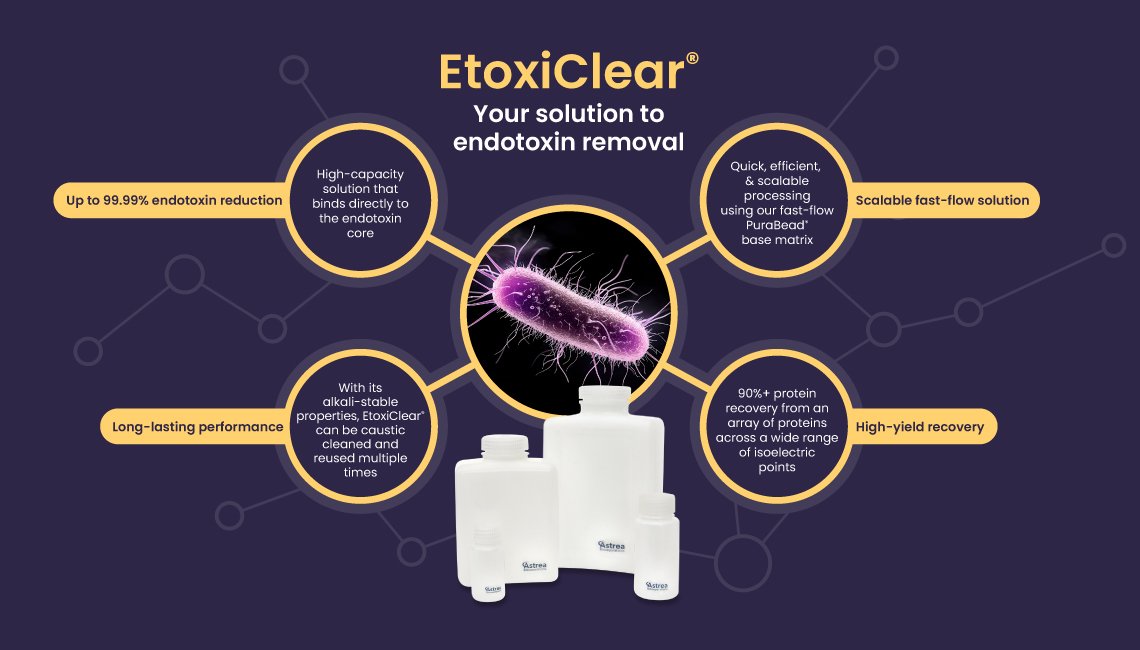

EtoxiClear® is an advanced endotoxin removal resin designed for high-capacity endotoxin removal across pharmaceutical, biotechnology, and research applications. With superior endotoxin clearance, high protein recovery, and process scalability, it ensures efficient and cost-effective removal of bacterial endotoxin from proteins, buffers, and other biological solutions.

EtoxiClear® was developed to address these challenges, offering a more efficient, versatile, and cost-effective alternative for ensuring safe and pure products.

Here's how it outperforms traditional methods:

- Leading Player in Endotoxin Removal: EtoxiClear® can remove more endotoxins in one go compared to many other market products. Our patented resin achieves up to 99.99% reduction in endotoxins.

- Higher Protein Recovery: When removing endotoxins, protein yield recovery can be significantly impacted, as seem by other employed methods such as Ion Exchange chromotography. EtoxiClear® achieves >90% protein recovery from an array of proteins.

- Wide Range of Operating Conditions: EtoxiClear® works across a wide pH range (pH 4.0 to 8.0) and salt conditions, making it suitable to use across broad range of applications and target proteins.

- Faster and More Efficient: EtoxiClear® uses our fast flow PuraBead® base matrix. When packed in a column and operated in flow-through mode, polishing endotoxin is quicker and more efficient.

- Reusable and Cost-Effective: EtoxiClear® can be regenerated and reused using a simple 0.5 M NaOH wash, maintaining its high endotoxin binding capacity over multiple cycles. This reusability leads to lower cost per run and significantly reduces overall production expenses.

- Compatible with More Applications: EtoxiClear® can be used with a wide variety of products, including antibodies, vaccines, recombinant proteins, diagnostic reagents, and more.

Why EtoxiClear® is Superior to Traditional Endotoxin Removal Methods

EtoxiClear® is a next-generation solution specifically engineered to overcome the limitations of traditional endotoxin removal methods. Endotoxins, which are harmful toxins from the cell walls of gram-negative bacteria, can contaminate products during production and pose serious risks if not effectively removed. These toxins can cause fevers, inflammation, and even life-threatening reactions, especially in injectable drugs, vaccines, and therapeutic proteins.

In the past, methods like ion-exchange (IEX) membranes, ultrafiltration, and affinity-based membranes have been widely used. However, these traditional approaches have significant limitations, including lower efficiency, protein loss, narrow pH compatibility, and high operational costs.

Simplified Workflow Integration and Scalability

EtoxiClear® is designed for seamless integration into existing purification processes. Available in multiple column sizes for research or process-ready applications and bulk adsorbent slurry, ensuring scalability from lab-scale R&D to large-scale manufacturing.

EtoxiClear® is a market leading solution trusted by large industry players to ensuring safe, pure, and high-quality products across a wide range of applications. It provides a powerful advantage over traditional endotoxin removal methods, helping manufacturers achieve higher efficiency, reliability, and compliance.

Request an EtoxiClear® Sample Today!

Experience the efficiency and reliability of EtoxiClear® firsthand! Whether you’re optimizing endotoxin removal for biopharmaceuticals, research, or industrial applications, our sample program allows you to evaluate EtoxiClear® in your specific workflow.

Request sample here

Specifications

Product Specifications

| Feature | Details | Why It Matters? |

|---|---|---|

| Technology | Synthetic ligand-based adsorbent | Provides highly specific and efficient endotoxin binding while maintaining high protein recovery. |

| Base Matrix | PuraBead® | Ensures durability, high flow rates, and low non-specific binding. |

| Endotoxin Binding Capacity | >1,000,000 EU/mL of adsorbent | Industry-leading capacity for efficient removal of endotoxins. |

| Mode of Operation | Flow-through chromatography | Fits into existing purification workflows. |

| Protein Recovery | >90% across a wide range of proteins | Maximizes yield while maintaining purity. |

| Column Pre-packing | 5 mL to 30L | Available pre-packed for flexible scalability, suitable for R&D, pilot studies, and large-scale manufacturing in a seemless plug-in format |

| Operating pH Range | 4.0 – 8.0 | Works in a wide range of operating conditions, making it adaptable for different protein formulations. |

| Optimal Flow Rate | Up to 200 cm/hr | Ensures rapid processing without compromising binding efficiency. |

| Regeneration & Depyrogenation | 0.5 M NaOH | Enables reuse while maintaining high endotoxin clearance, reducing operational costs. |

| Storage Conditions | 2 – 30°C 20% ethanol : 80% 0.1 M NaCl (v/v) | Stored in preservative for stability and antimicrobial storage. |

| Shelf Life | 5 years | Reliable long-term performance for consistent results. |

| Regulatory Compliance | Designed for cGMP manufacturing | Suitable for regulatory-compliant biopharmaceutical production processes, complete with regulatory support file. |

| Comparison to IEX & Affinity Membranes | High endotoxin removal efficiency (Up to 99.99%), higher protein recovery (>90%) | Outperforms conventional methods, providing greater yield and purity. |

Request an EtoxiClear® Sample Today!

Experience the efficiency and reliability of EtoxiClear® firsthand! Whether you’re optimizing endotoxin removal for biopharmaceuticals, research, or industrial applications, our sample program allows you to evaluate EtoxiClear® in your specific workflow.

Request sample here

Applications

Uses of EtoxiClear® for Endotoxin Removal

- Monoclonal antibodies, bispecific and other antibody formats

- Recombinant Proteins & Enzymes expressed in bacterial systems like E. coli, maintaining protein integrity and activity.

- Vaccine Production

- Plasma-Derived Proteins

- Diagnostic & Research Applications

- Biosimilar Production

- Hormone & Growth Factor Purification

- Bioprocessing & GMP Manufacturing

- Biotechnology & Academic Research

Request an EtoxiClear® Sample Today!

Experience the efficiency and reliability of EtoxiClear® firsthand! Whether you’re optimizing endotoxin removal for biopharmaceuticals, research, or industrial applications, our sample program allows you to evaluate EtoxiClear® in your specific workflow.

Request sample here

FAQs

Frequently Asked Questions

What is EtoxiClear®?

EtoxiClear® is a high-performance chromatography adsorbent designed for efficient and cost-effective endotoxin removal.

What are the key features of EtoxiClear®?

- Endotoxin clearance to below 0.1 EU/mg protein

- Endotoxin clearance of ≤ 0.05 EU/mL from various buffers

- Compatible with a wide range of proteins

- Dynamic binding capacity of >1,000,000 EU/mL

- Stable in commonly used buffer solutions

- Can be cleaned/depyrogenated in 0.5 M to 1.0 M NaOH

What formats is EtoxiClear® available in?

EtoxiClear® is available pre-packed columns ready to plug into your research or GMP process. It is also available in slurry format.

What is the recommended operational flow rate for EtoxiClear®?

The recommended operational flow rate is up to 200 cm/hr, depending on column size. A flow rate of 120 cm/hr with a ≥5-minute residence time is recommended for optimal performance.

What is the pH stability of EtoxiClear®?

EtoxiClear® is stable in the long term (3 months) from pH 3 to pH 12. The recommended operating pH range for endotoxin binding applications is pH 4.0 to pH 8.0.

How should EtoxiClear® be stored?

The recommended storage condition is 2-30°C in 20% ethanol / 80% 0.1 M NaCl (v/v).

How is EtoxiClear® regenerated?

EtoxiClear® can be regenerated by passing 2 CV of 0.5 M NaOH through the column, followed by an overnight hold in 0.5 M NaOH (>16 hours). After the hold, flush with 1 CV of 0.5 M NaOH and wash with equilibration buffer until pH matches.

- Monoclonal antibodies (mAbs), bispecifics, and other antibody formats

- Recombinant proteins and enzymes

- Vaccines

- Plasma-derived proteins such as albumin and clotting factors

- Peptides, hormones, and growth factors

- Diagnostic reagents and other research applications

Request an EtoxiClear® Sample Today!

Experience the efficiency and reliability of EtoxiClear® firsthand! Whether you’re optimizing endotoxin removal for biopharmaceuticals, research, or industrial applications, our sample program allows you to evaluate EtoxiClear® in your specific workflow.

Request sample here

No video available.