- Home

- |

- Products

- |

- PuraBead® Resins

- |

- IEX

- |

- SP PuraBead® Edge

SP PuraBead® Edge

SP PuraBead® Edge is a next-generation strong CEX adsorbent, featuring a sulphopropyl (SP) group attached to our advanced 65 µm PuraBead® Edge base bead. Our PuraBead® Edge resin is engineered for high resolution polishing applications offering short residence times and low back pressure. This resin is designed to enhance separation resolution, ideal when required for the capture and polish of positively charged species.

Product overview

Product overview

SP PuraBead® Edge is a next-generation strong cation exchange (CEX) adsorbent, featuring a sulphopropyl (SP) group attached to our advanced 65 µm PuraBead® Edge base bead. Our PuraBead® Edge resin is engineered for high resolution polishing applications offering short residence times and low back pressure. This resin is designed to enhance separation resolution, ideal when required for the capture and polish of positively charged species. Efficiently remove unwanted mispaired species and aggregates from bispecific antibody feeds or reduce host cell proteins (HCPs) from CHO IgG with ease.

What are the key features of SP PuraBead® Edge?- Improved resolution using our 65 µm PuraBead® Edge base bead

- Optimal balance of flow rate, binding capacity, and resolution to maximize productivity

- Demonstrated performance in antibody applications

- Efficient processing of large volumes

In application: Bispecific antibody polishing

Bispecific antibodies (BsAb) aggregates can trigger immune responses in patients and must be removed via purification processes, which can impact overall purification yields. While Protein A can still be used in the initial capture step of BsAbs, subsequent polishing steps must efficiently separate correctly assembled bispecifics from mispaired species, aggregates, and other impurities. The heterogeneity introduced by bispecific antibody production requires additional purification strategies, such as orthogonal chromatographic techniques, to ensure a final product with high purity and functionality.

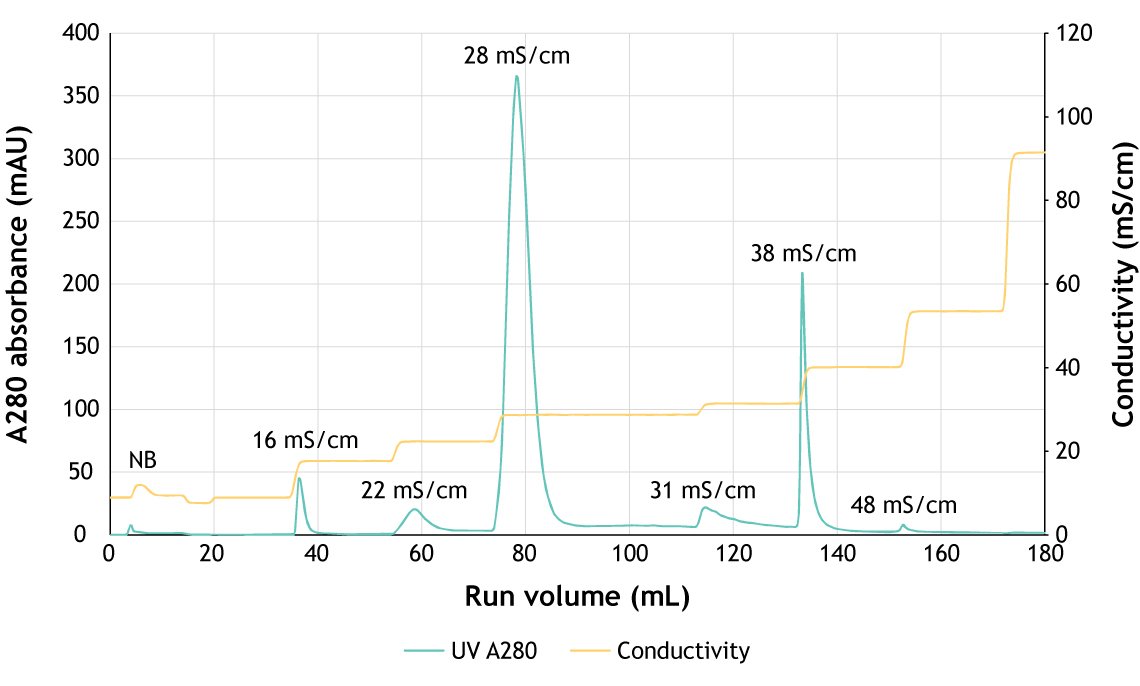

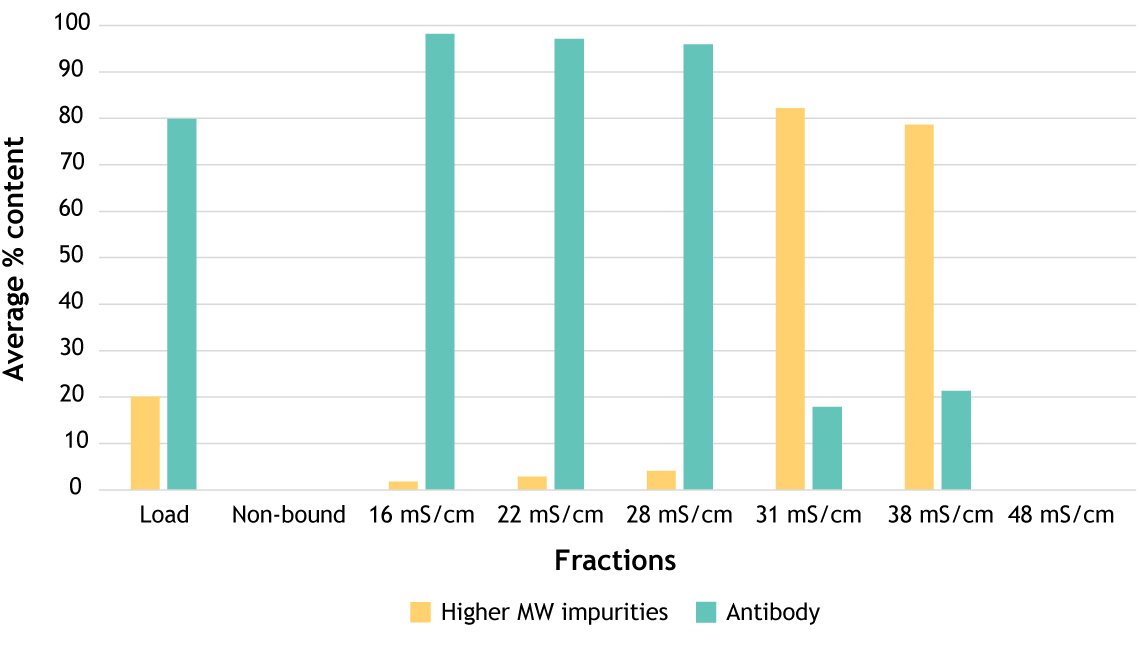

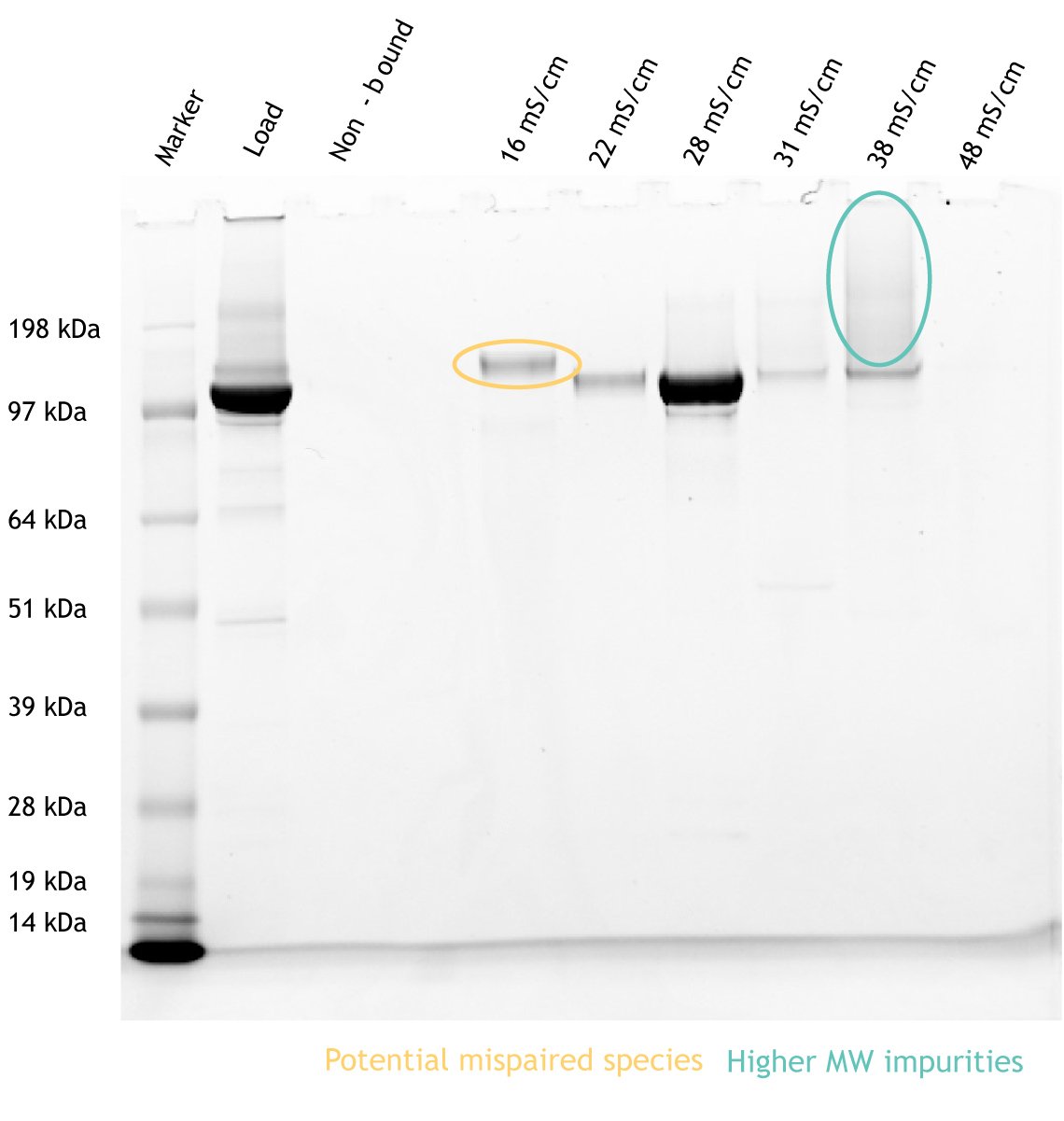

SP PuraBead® Edge cation exchange (CEX) adsorbent leverages the differences in charge interactions to achieve high resolution separation of the desired BsAb from unwanted mispaired species, aggregates and other impurities. Typically, the target protein binds to the resin in a low-salt buffer at a pH below its isoelectric point (pI), allowing it to interact with negatively charged functional groups. Aggregates often exhibit stronger binding, allowing them to be effectively separated by manipulating the conductivity levels of the elution, with BsAb eluting first, followed by aggregates at higher salt concentrations. Slight variation in charge density of the product impurities (mispaired variants and fragments) also allows separation by manipulating salt levels in the elution. This polishing has been demonstrated using SP PuraBead® Edge, post-Protein A affinity using differing conductivity (Figure 1). The result of this study demonstrated a BsAb aggregate reduction from 20% in the load (post-Protein A bispecific feed) to <5% with the use of an optimized step elution, as shown in Figure 2. SDS-PAGE analysis of the fractions (Figure 3) demonstrates not only the reduction in aggregate content but also the effective separation of mispaired species and other unwanted byproducts, highlighting the versatility of SP PuraBead® Edge in improving both purity and functionality.

Figure 1. Chromatogram showing Protein A affinity purified bispecific feed loaded onto a SP PuraBead® Edge column (20 cm bed height) and eluted with step increases of 1 M NaCl elution buffer, conductivities at which peaks eluted are annotated in black text.

Figure 2. Using SP PuraBead® Edge for BsAb aggregate reduction (post-Protein A bispecific feed), reducing from 20% to <5% using an optimized step elution. Average percentage of higher molecular weight (MW) impurities (yellow) and antibody (teal) content determined by fluorescence SEC analysis. Graph shows the calculated percentage content for the load, non-bound, and each elution step fraction.

Figure 3. Post-polishing with SP PuraBead® Edge demonstrating the separation of unwanted impurities. SDS-PAGE analysis of the load, non-bound, and each elution step fraction. Band circled in yellow represents potential mispaired species. Banding circled in teal represents higher molecular weight (MW) impurities. The main target product is seen in the 28 mS/cm elution fraction at approximately 125 kDa.

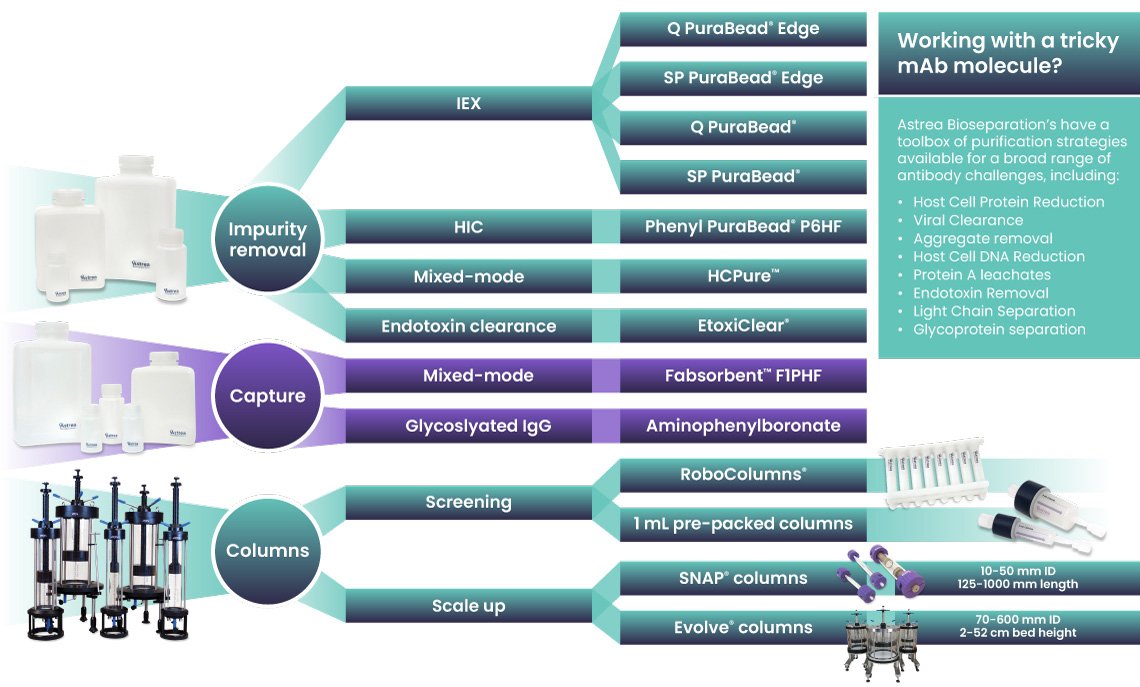

Astrea Bioseparations: A complete toolbox for antibody purification

As the demand for novel antibody formats grows, efficient screening of purification conditions becomes essential. Astrea Bioseparations has a broad range of purification resins, ranging from capture to polish, for mAb and other antibody formats. Using Astrea Bioseparations' toolbox approach, products, such as Fabsorbent™ F1P HF, HCPure™, Q PuraBead® and SP PuraBead® Edge, provide the market with additional choices for downstream processing workflows. Resins are provided in high-throughput screening formats to streamline discovery and purification. Combining smarter purification strategies and high-throughput screening options will help shape the future of biopharmaceutical development and commercialization of new drugs.

Simplified workflow integration and scalability

SP PuraBead® Edge is designed for seamless integration into existing purification processes. Available in multiple column sizes for research or process-ready applications and bulk adsorbent slurry, ensuring scalability from lab-scale R&D to large-scale manufacturing.

SP PuraBead® Edge is a solution trusted by industry players to ensuring safe, pure, and high-quality antibody products. It provides a powerful alternative over traditional monoclonal antibody capture & purification methods, helping manufacturers achieve efficiency, reliability, and compliance.

Product specifications

Product specifications

| Property | Value |

|---|---|

| Ligand | Sulphopropyl group |

| Type of ion exchanger | Strong cation |

| Total ionic capacity | 97 to 163 µmol/g settled gel |

| Mean particle size (µm) | 65 ± 10 µm |

| Matrix | PuraBead® P60HF(Highly cross-linked 6% near-monodisperse agarose) |

| Binding capacity | Up to 95 mg/mL of resin (Lysozyme, when loaded to 10% breakthrough) |

| Recommended packing conditions | Pack at a constant pressure of up to 3.5 bar |

| Recommended packing solution | 1 M NaCl solution |

| Recommended operational flow rates | Up to 400 cm/h |

| Operating pH | pH 4.0 to pH 14.0 |

| Chemical stability | All commonly used aqueous buffers and co-solvents |

| Cleaning/sanitization | 0.5 to 1.0 M NaOH |

| Sterilization | Autoclavable in 0.1 M NaCl solution at 121°C for 30 minutes |

| Storage | 2–30°C, 20% ethanol, 0.2 M sodium acetate |

Frequently asked questions

Frequently asked questions

What is SP PuraBead® Edge?

SP PuraBead® Edge is a next-generation strong CEX adsorbent, featuring a sulphopropyl (SP) group attached to our advanced 65 µm PuraBead® Edge base bead.

What are the key features of SP PuraBead® Edge?

- Improved resolution using our 65 µm PuraBead® Edge base bead

- Optimal balance of flow rate, binding capacity, and resolution to maximize productivity

- Demonstrated performance in antibody applications

- Efficient processing of large volumes

What formats is SP PuraBead® Edge available in?

SP PuraBead® Edge is available in pre-packed columns ready to plug into your research or GMP process. It is also available in slurry format.

What is the recommended operational flow rate for SP PuraBead® Edge?

The recommended operational flow rate is up to 400 cm/hr, depending on column size.

What is the pH stability of SP PuraBead® Edge?

The recommended operating pH range for SP PuraBead® Edge is 4 to 14.

How should SP PuraBead® Edge be stored?

The recommended storage condition is 2-30°C in 20% ethanol, 0.2 M sodium acetate.

How is SP PuraBead® Edge regenerated?

Removal of any residual adsorbed material can be achieved by washing the column with 0.5-1.0 M NaOH. A contact time of 1 hour will normally suffice to ensure destruction of viable organisms, although up to 5 hours contact time may be required. No less than 5 column volumes are recommended. Once cleaning with NaOH is complete, wash with at least 3 bed volumes of equilibration buffer until the pH and conductivity of the column eluate is equal to that of the buffer entering the column. Complete this process prior to further use or storage in the storage buffer.

What types of biomolecules can SP PuraBead® Edge be used with?

- Across broad range of applications and feedstocks

- Where removal of unwanted mispaired species and aggregates is required from bispecific antibody feeds

- Where polishing of host cell proteins from IgG is required

- Where high resolution polishing with short residence times and low back pressure is required

Astrea Bioseparations has a broad range of purification resins, ranging from capture to polish, for mAb and other antibody formats. Using Astrea Bioseparations' toolbox approach, products, such as Fabsorbent™ F1P HF, HCPure™, Q PuraBead® and SP PuraBead® Edge, provide the market with additional choices for downstream processing workflows. Resins are provided in high-throughput screening formats to streamline discovery and purification. Combining smarter purification strategies and high-throughput screening options will help shape the future of biopharmaceutical development and commercialisation of new drugs.

Related Products

Recently Viewed

There are no recently viewed products.

No video available.